Customer

An industrial OEM specializing in the precision manufacturing of large server room doors, primarily for Google’s data centers. The company is dedicated to high-quality industrial machining, with a strong focus on precision and strict quality control throughout the production process.

Business Type

- Original Equipment Manufacturer (OEM)

- Industrial Machining Company

Product

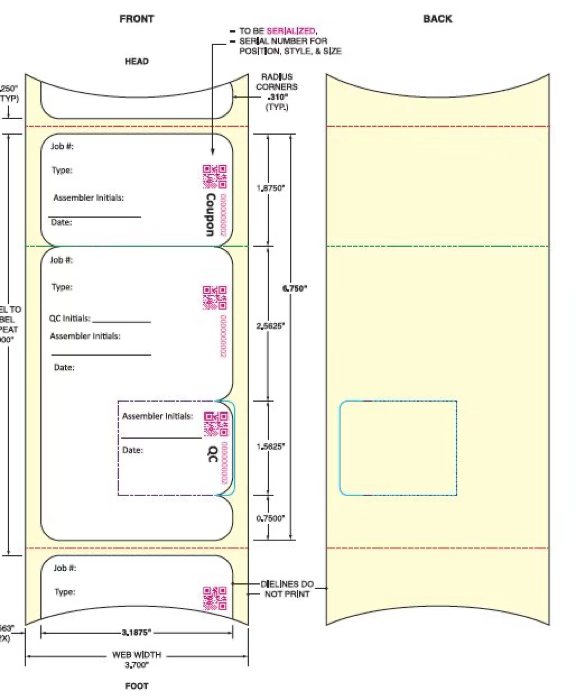

A unique one of a kind Piggyback label

Problem

Our client struggled with tracking doors through their three-stage production workflow (manufacturing, quality control, and shipping). Their existing solution using separate Avery labels printed on thermal transfer printers created multiple problems:

- Standalone labels frequently became separated between stations

- Misprints and duplicate serial numbers caused confusion

- QC verification was compromised when labels couldn't be matched

- Installation teams required matching serial numbers and signatures across multiple labels

The critical issue: if serial numbers didn't match between door labels and QC logs, the doors couldn't be installed per protocol, causing costly delays.

Condition

Our customer needed a unified label system that could:

- Keep three serialized labels together throughout production

- Allow writing on each label portion for signatures

- Be easily handled by workers wearing surgical gloves

- Separate cleanly for different tracking purposes

- Eliminate misprints and duplicates

Solution

We engineered a specialized three-part piggyback label with matching serial numbers featuring:

- A top label with perforation for easy tear-off and placement in shipping boxes

- A middle door-mounted label that houses the QC component

- An embedded QC label with a slit-over-perforation design

The breakthrough design element was creating a QC label that could be accessed while wearing surgical gloves by implementing a tear-out system where the QC label and its liner could be cleanly removed from the middle label. This slit-over-perforation approach allowed workers to tear out the third label and easily peel it from its liner for placement in QC logs.

This custom solution eliminated all previous tracking issues. With Steven Label printing consistent serial numbers, our client now produces approximately 100,000 of these specialized labels annually with:

- Zero separation between tracking labels

- No misprints or duplicate numbers

- Streamlined quality control process

- Improved installation verification

The unique construction ensures complete traceability through all production stages while accommodating their specific handling requirements.